Production Line

The Production Line module defines the configuration of each production line within the manufacturing setup.

It establishes how a line operates — including the supervisors, operators, linked production mapping, and the maximum production capacity.

This ensures that every production line is clearly defined, well-monitored, and aligned with the company’s manufacturing plan.

Users can add, edit, or delete production lines as required.

Purpose

A Production Line serves as a central unit in the manufacturing process.

It brings together human resources (supervisors and operators), machinery, and process flow (via production mapping) to ensure smooth and continuous production.

Proper setup of production lines helps in optimizing resource utilization and improving efficiency.

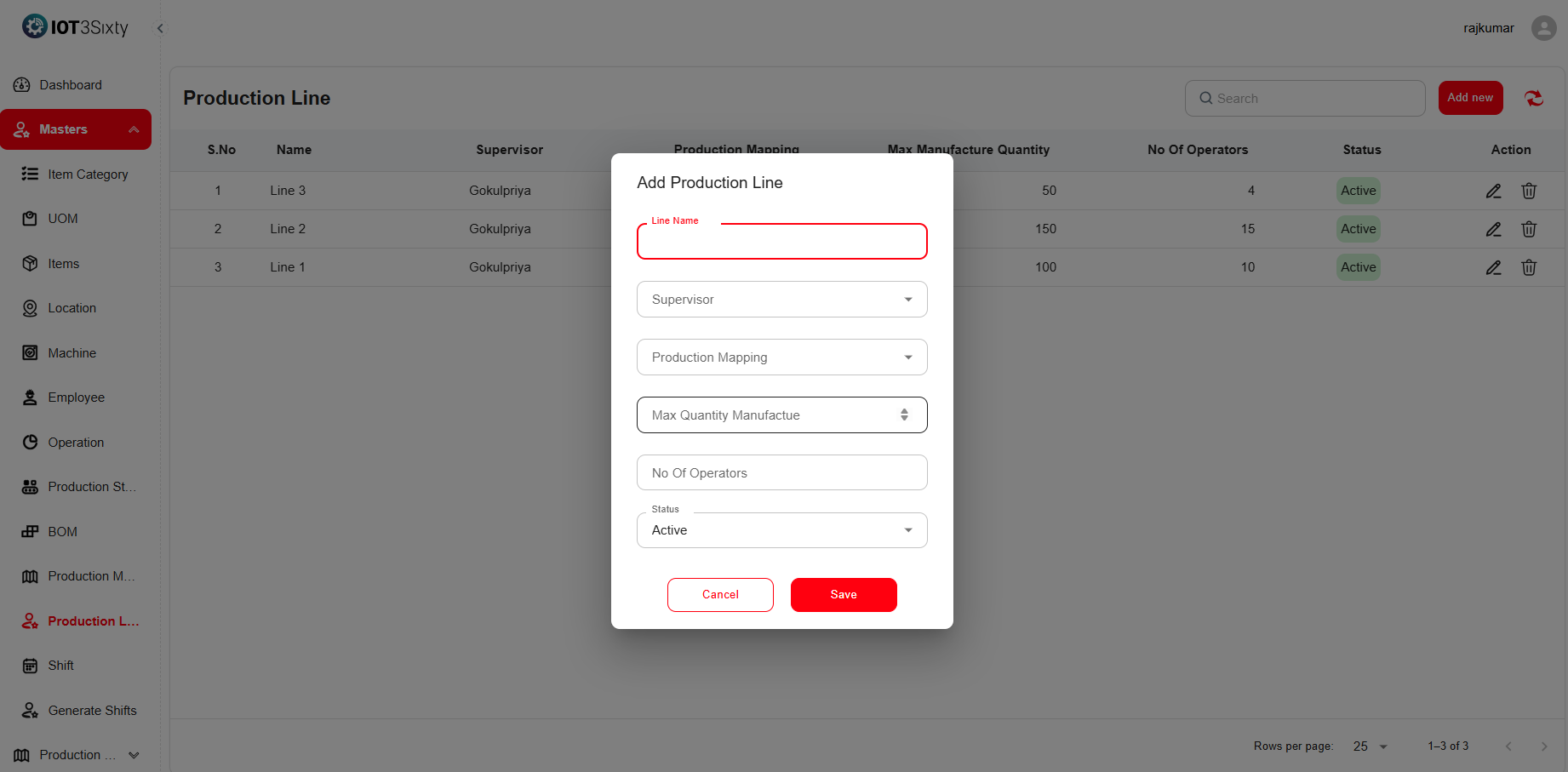

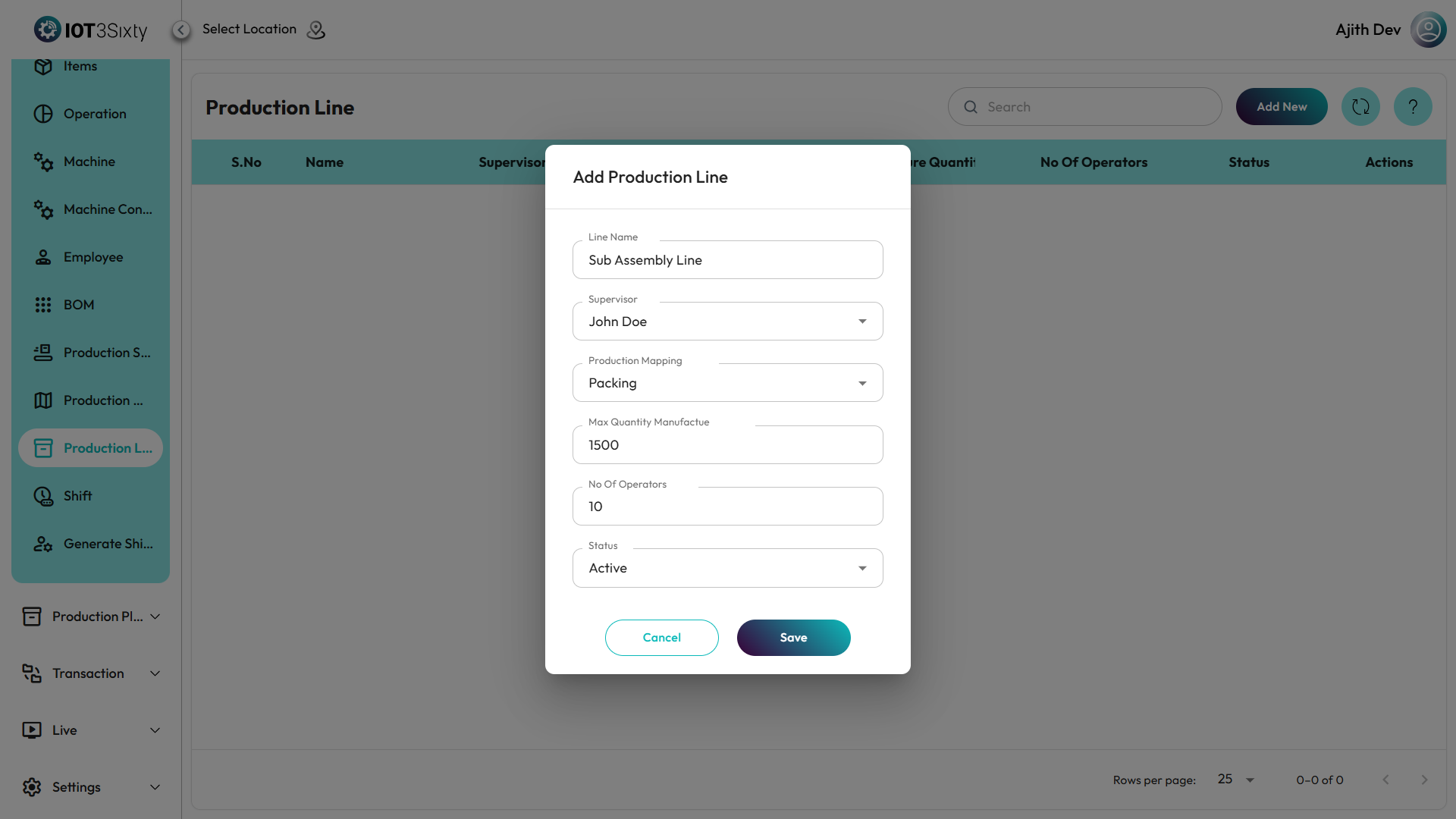

Steps to Add or Manage a Production Line

-

Navigate to the Production Line Menu.

-

Click Add New to configure a new production line.

-

Fill in the following details:

Field Description Line Name Provide a unique name for the production line (e.g., Assembly Line 1). Supervisor Select the supervisor responsible for overseeing the line’s operations. Production Mapping Choose the production mapping that defines the process flow for this line. Maximum Quantity to Manufacture Enter the total number of items that can be produced in one cycle or shift. Number of Operators Specify the count of operators required to run this production line efficiently. Status Set to Active or Inactive, depending on the line’s availability. -

Click Save to confirm and store the production line details.

Additional Options

- Edit: Update details such as supervisor, operators, or production capacity when changes occur.

- Delete: Remove inactive or obsolete production lines to maintain data accuracy.

Benefits

- Clearly defines responsibilities and team structure for each production line.

- Helps monitor production limits and manage workforce allocation.

- Ensures that all production lines follow standardized mapping and workflows.

- Provides better control, traceability, and efficiency across manufacturing units.