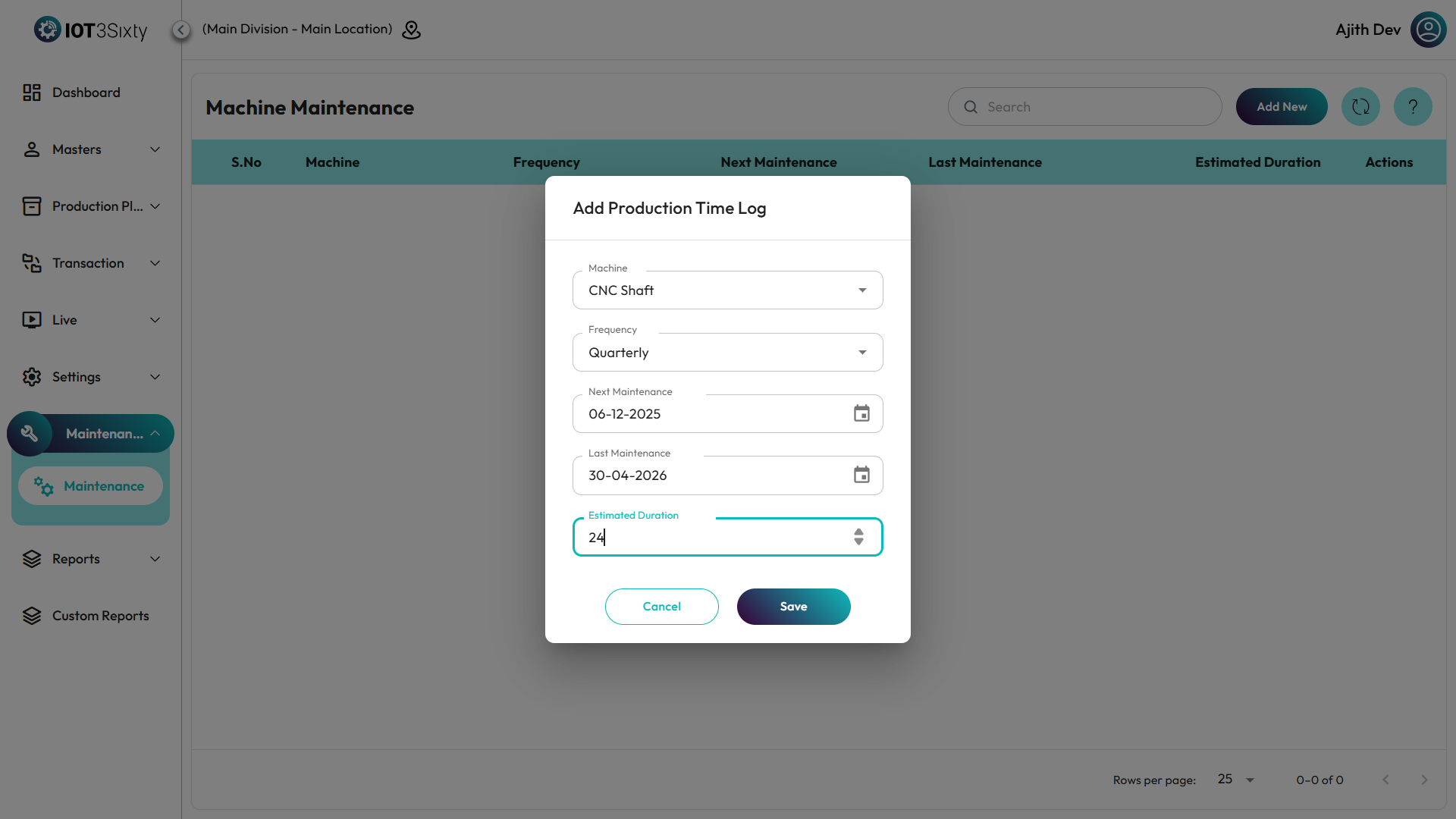

Machine Maintenance

The Machine Maintenance feature allows users to schedule and track maintenance activities for machines in the production process. It helps ensure that machines are functioning optimally and reduces downtime.

Maintenance Frequency

- Define how often maintenance should be performed for each machine.

- Options include Yearly, Monthly, or Quarterly, based on the machine’s requirements and usage.

Next Maintenance Date

- The Next Maintenance Date is automatically calculated based on the frequency and last maintenance date.

- It helps schedule when the next maintenance activity is due, reducing the risk of missed maintenance tasks.

Last Maintenance Date

- The Last Maintenance Date records when the machine was last serviced.

- This provides historical data on machine maintenance and ensures that maintenance is performed at appropriate intervals.

Estimated Duration

- The Estimated Duration indicates the time required to complete the maintenance activity.

- This helps in planning downtime efficiently and minimizing production disruptions.

This section provides a clear explanation of how machine maintenance is scheduled and tracked, ensuring proper maintenance intervals for smooth and efficient production operations.