Operation

The Operation Master defines and manages the various operations involved in the production process within the MES system.

Each operation represents a specific stage or task in manufacturing — such as Assembly, Welding, Inspection, or Packing.

This module helps standardize processes, monitor production efficiency, and manage costs accurately.

Purpose

The Operation Master allows users to:

- Define the sequence of operations in the production cycle.

- Set standard time and cost for each operation, improving planning and scheduling accuracy.

- Maintain consistent operation definitions across divisions and departments.

- Support cost control and performance tracking by establishing measurable benchmarks.

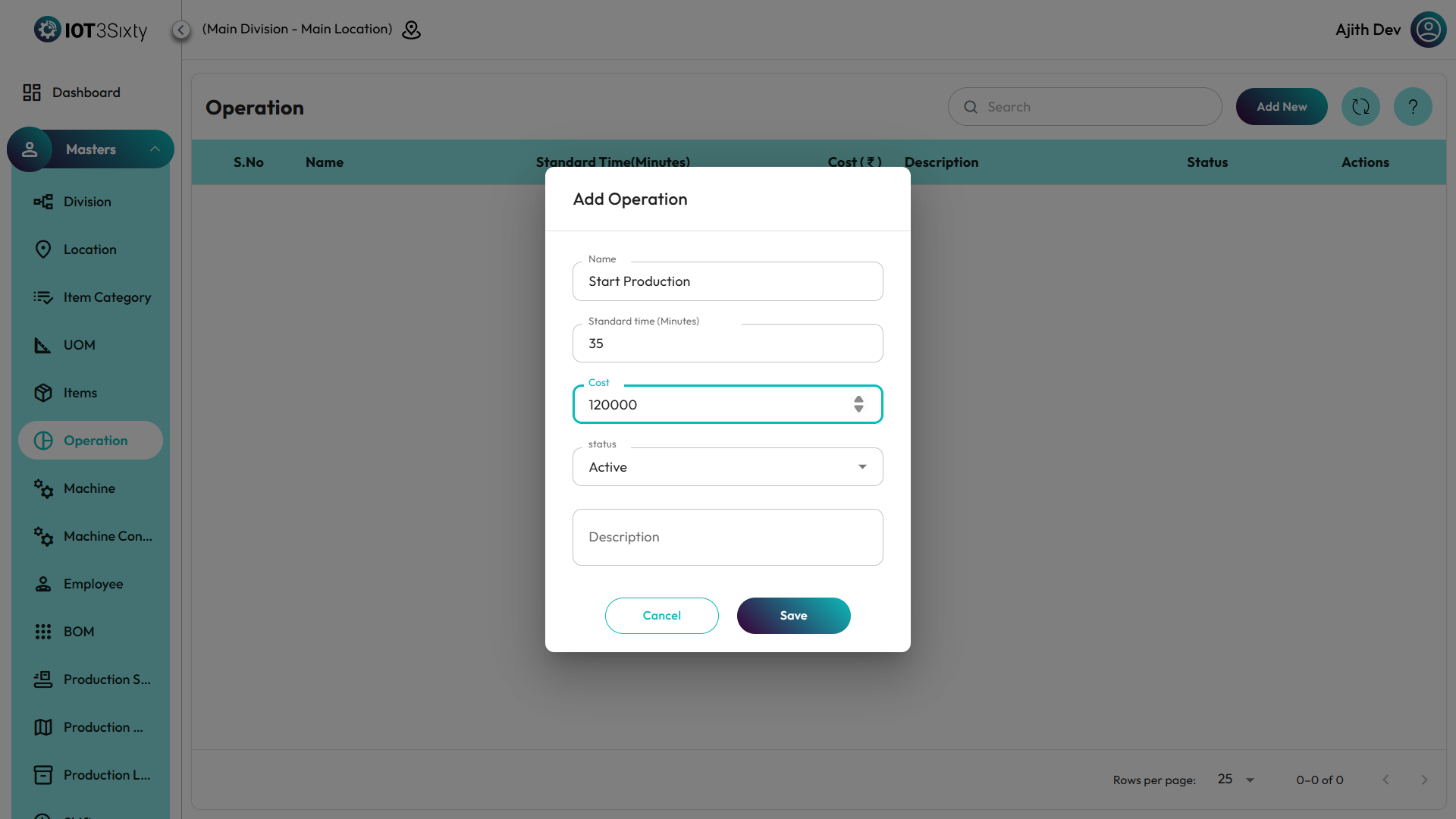

Steps to Add a New Operation

- Navigate to the Operation menu from the main MES Dashboard.

- Click on the Add New button to create a new operation entry.

- Enter the Operation Name (for example: Assembly, Painting, Cutting, Inspection).

- Specify the Standard Time required to complete this operation.

- Time can be entered in minutes or hours, depending on the process requirements.

- Enter the Standard Cost associated with performing this operation.

- This helps in calculating production cost and resource utilization.

- Click Save to store the operation details in the system.

Operation Details Displayed

Once operations are added, the list displays the following information:

- Operation Name – The name of the process step (e.g., Assembly, Welding).

- Standard Time – The estimated duration to complete one cycle of the operation.

- Standard Cost – The predefined cost associated with performing the operation.

- Status – Indicates whether the operation is Active or Inactive.

- Action – Allows you to Edit and Delete of the operation.

Additional Features

- You can filter or search for operations using the search bar.

- Use the Refresh Icon to update the operation list after making any changes.

- In case of process updates, you can edit existing operations to modify time or cost.

- Deactivating an operation prevents it from being assigned to new production orders but keeps its history intact.

✅ Tip:

Keep your operation definitions clear and standardized across all divisions.

Accurate time and cost values improve production scheduling, resource planning, and profitability analysis.